Investment Opportunity

Investors today have many choices, each with varying degrees of risk. While technology is exciting, it can be difficult to understand and evaluate. Many investments are promoted using historical data and charts, but actual returns often fail to meet expectations. While companies like Amazon, Tesla, and Google have achieved massive success, they represent a small fraction of the market. As Warren Buffet wisely stated: “We do not invest in what we do not understand.”

The Growing Beer Market

History confirms that change is constant. Since the rise of small-scale brewing in the 1980s, the global beer market—currently valued at $650 billion, is projected to reach a $1 trillion valuation — has seen significant shifts. Our experience in television production and demographic research identified a unique opportunity to apply a Coca-Cola-style business model to beer. Over 35 years, we have developed patented solutions that enhance profitability in both consumer and hospitality markets.

Beer is a universally understood product, and craft beer has gained popularity due to consumer demand for fresh, high-quality, locally brewed options. Large beer brands struggle to compete, leading them to acquire successful craft breweries.

Our products, The Beer Machine® and HausCraftBeer™, have a key advantage: they do not distribute alcohol—only equipment and ingredients. This allows for rapid scaling, unrestricted by alcohol regulations. A successful scale-up could position the brands for a lucrative buyout by established industry players.

A Different Approach to Brewing

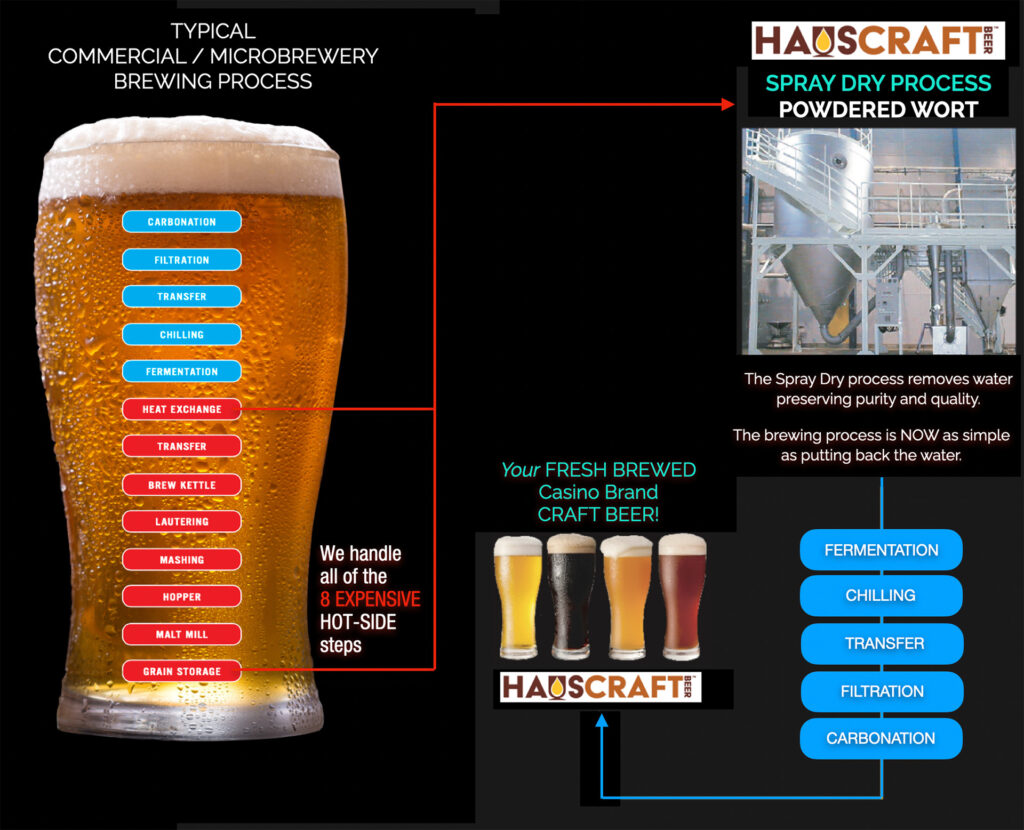

Instead of competing directly with beer brands, we have innovated a superior patent-protected brewing process with little direct competition.

- The Beer Machine® simplifies home brewing, making it convenient and economical for beer consumers worldwide.

- HausCraftBeer™ provides automated commercial brewing equipment for large restaurants, casino resorts, sporting facilities, vacation resorts, entertainment facilities and cruise ships, reducing costs and eliminating labor-intensive processes.

- Brewing costs range from $0.35 to $0.55 per pint, while retail prices range from $6 to $10 per pint —hospitality venues gain a significant profit margin.

- Branding options allow venues to market their own craft beer in cans and growlers.

Instead of competing directly with beer brands, we have innovated a superior patent-protected brewing process with little direct competition.

The Global Beerco technology revolutionizes brewing by eliminating high capital and operational costs. Traditional brewing requires significant real estate space, labor, and resources, but our streamlined process simplifies production and reduces expenses. White Paper by Dr Michael J Lewis.

Patented Brewing Innovation

Our brewing technology, developed under the guidance of Dr. Michael J. Lewis, professor emeritus of brewing sciences at UC Davis, eliminates the costly “Hot Side” of traditional brewing.

The process relies on Bag-to-Bag technology, which reduces labor, water use, and exposure to harmful chemicals. This

innovation:

- Eliminates the need to sanitize brewing tanks between batches.

- Reduces water consumption from 10 gallons to just 1.5 gallons per gallon of beer produced.

- Cuts operating costs while ensuring consistency and quality.

- Eliminates harmful chemicals used in traditional brewing.

- Aligns with conservation and eco friendly policy.

By eliminating the costly “Hot Side” of brewing, both The Beer Machine® for consumers and the HausCraftBeer™ system operators concentrate exclusively on fermentation, optimizing the cold-stage process. This efficient method utilizes pre-prepared powdered ingredients, with brewer’s yeast completing the transformation into beer. The result is a cost-effective, high-quality brewing process that delivers exceptional value.

A Proven Business Model

Our model follows the success of industry giants:

- Elon Musk did not invent the car—he adapted new technology to improve it.

- Coca-Cola does not make its beverage—it produces a syrup and licenses bottlers for distribution.

- Sierra Nevada and other craft beer giants started as homebrewers before scaling up.

The Beer Machine® and HausCraftBeer™ follow a similar approach—leveraging technology to streamline brewing, cut costs, and drive growth.

Market Validation & Growth Potential

- The Beer Machine® has generated tens of millions in retail sales.

- HausCraftBeer™ is installed in leading casino resorts and restaurants.

- Strong interest from cruise lines, sports bars, ski lodges, and entertainment venues.

- Our business model positions us for 10x ROI for early investors.

Eight Key Investment Factors

- Unique & Patented Technology – Multiple U.S. patents protect our brewing innovations, now enhanced with IoT monitoring.

- Long-Term Market Viability – The beer industry is 5,000 years old. Our systems are designed for long-term pro!tability within a stable, recession-resistant market.

- Technology Advantages – Patented Bag-to-Bag technology eliminates costly complex brewing steps and costs, increasing margins.

- Solves Industry Challenges – Lowers overhead, eliminates labor-intensive processes, and enhances sustainability. Follows a centralized ingredient production model similar to Coca-Cola.

- Expansive Market Opportunity – A $650 billion industry forecast to reach $1 Trillion by 2032 with untapped eCommerce and hospitality growth. Our solutions are free from alcohol distribution regulations, allowing for rapid global expansion.

- Clear Competitive Edge – Strong pricing advantage and proprietary brewing process create high barriers to entry. Established mass-production capability ensures cost advantages.

- Defined Exit Strategy – Opportunities for mergers, acquisitions, or public offering within 3–5 years. Increasing installations enhance enterprise value for a strategic buyout.

- Experienced Management Team – A seasoned team with deep expertise in brewing, consumer sales, and scaling global brands. Backed by expert brewers from UC Davis. Supported by marketing strategies including trade shows, digital campaigns, and industry events.

Conclusion

HausCraftBeer™ Marketing LLC offers a compelling investment opportunity through an operation agreement with GlobalBeerco USA, Inc, backed by patented innovation, strong market demand, and a proven business model. With strategic funding, Global Beerco’s product lines are positioned for substantial growth and long-term profitability. Investors seeking high ROI potential with a clear exit strategy should consider the unique features of the HausCraftBeer™ Marketing LLC. This prime investment opportunity includes profit sharing and share conversion in two award-winning product lines, both strategically positioned for growth in one of the world’s largest and most enduring consumer markets.

Many of today’s most successful companies—Amazon®, Tesla®, Netflix®, and Uber®—disrupted their industries by leveraging new business models and emerging technologies. Well-funded, innovative companies in large markets can rapidly generate exceptional shareholder value. HausCraftBeer™ and The Beer Machine® represent the next wave of brewing innovation, poised to reshape the global beer market.

- © 2025 EagleWatch Capital Inc | All rights reserved